AR GLASS

Product description

INTRODUCTION

Anti-Reflective glass, also known as AR glass, is produced by using magnetron sputtering to form an anti-reflective film on the single or double faces of low iron glass, which greatly reduces the surface reflectivity of the glass. The highest light transmittance will reach 99% at a certain peak, and the surface reflectance will decrease from 8% to less than 1%, achieving high transmittance, low reflection, and true color restore.

MOST COMMENLY USED SIZE

3mm、3.2m、3.5mm、4mm、4.6mm、5mm

3660×2140mm、3660×2440mm、3660×3300mm

FEATURES

HIGH TRANSMITTANCE, LOW REFLECTION & NO SHADOWS

The highest peak visible light transmittance is 99%. The average visible light transmittance exceeds 97%. The average reflectance is less than 1%, and the lowest value is less than 0.5%, significantly improving the original brightness of LCD and PDP and reducing energy consumption.

ANTI-SCRATCH, WEAR-RESISTANT & RESISTANT TO CLEANING

The hardness of the AR glass film layer is equivalent to that of glass (higher than 6H), which can withstand various cleaning without damage to the film layer.

HIGH TEMPERATURE RESISTANCE & UV RESISTANCE

AR glass can withstand temperatures max 650 Celsius Degree (usually acrylic can only withstand temperatures of 80 Celsius Degree). When made into laminated glass, AR glass has certain UV resistance functions.

STRONG IMPACT RESISTANCE AND GOOD FLATNESS

The impact performance of 3mm AR glass is equivalent to 6mm acrylic, and the flatness of AR glass is much better than acrylic.

DATA SHEET

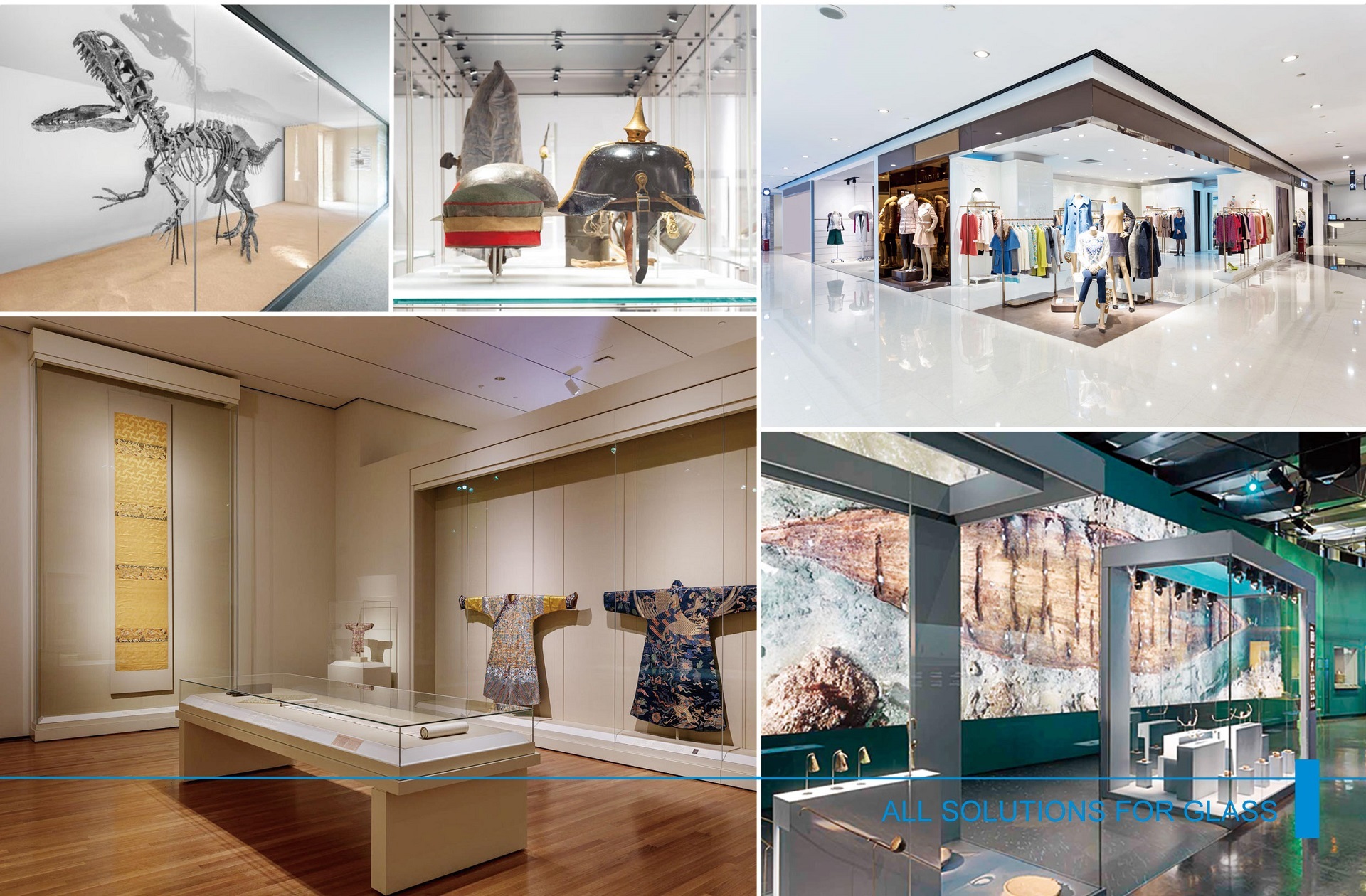

APPLICATION

Related Documents