TEMPERED GLASS

Product description

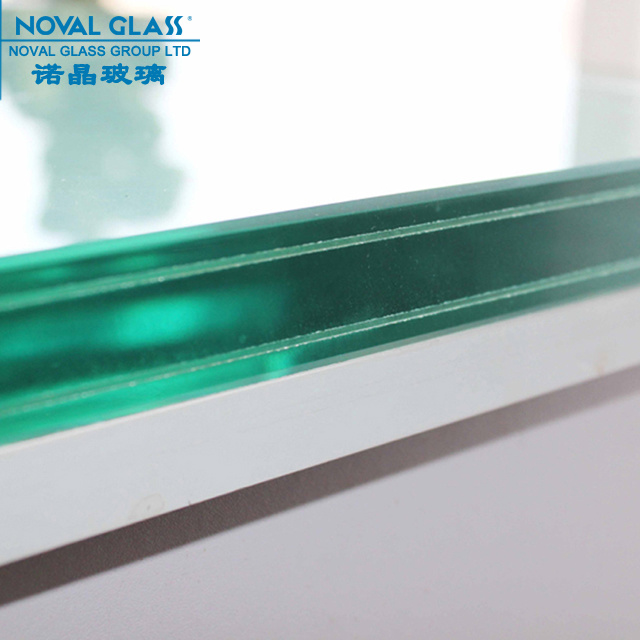

FLAT TEMPERED GLASS INTRODUCTION

Noval Glass Tempered Glass, also known as Toughened Glass, Safety Glass, is a heat toughened safety glass. It under goes a special heat treatment to provide significant increase of resistance to mechanical and thermal stresses than conventional annealed glass. When the glass breaks, it fragments safely into small pieces with dulled edges

FLAT TEMPERED GLASS FEATURES

▪ GOOD SAFETY -- If the glass break, Tempered Glass considerably reduces the risk of injury as it fragments into small pieces with dulled edges.

▪ GOOD IMPACT RESISTANCE -- Tempered Glass is approximately five times more resistant than normal glass. For example, a piece of 8mm toughened glass will be able to withstand a steel ball weighing 500g dropped from a height of 2 meters. For comparison, the same ball dropped from a height of 0.3 m will break 8mm normal annealed glass. The Tempered Glass has been tested in accordance with BS EN12600

▪ GOOD BENDING STRENGTH -- Tempered Glass is significantly more resistant to flexural stresses than conventional annealed glass. This resistance is characterized by a bending strength in the region of 120 Mpa (BS EN 12150).

▪ GOOD THERMAL-RESISTANCE -- Tempered Glass can withstand temperature differences of up to 200 centigrade. For comparison, it is around 30 centigrade for normal annealed glass.

▪ OTHER MORE -- Good performance of anti-pollution being cleaned easily clear and transparent. Good aging-resistance keeping transparent for long period quality that meets or exceeds the best in corresponding flat glass. Flexible production for truly custom glass, one piece or thousands

FLAT TEMPERED GLASS PRODUCTION PROCESSING

APPLICATION

NOVAL Tempered Glass is the perfect option for most situations which must meet safely requirements and where human contacts are an important consideration.

▪ BUILDING GLASS -- Windows, Curtain Walls, Guardrail, Overhead Glazing, Stair and Floor etc…

▪ DOORS & PARTITION -- Interior and Exterior Door, Glass Fa?ade and Partition, Shower Enclosure, Phone Booth and Bus Shelters etc…

▪ HOUSEHOLD ARTICLES -- Furniture Parts, Table Tops, Shelves, Chopping Board, Kitchen Splash Back, Home Appliance Panels and Coaster etc…

ROCESSING COMBINATION

Tempering is a basic processing for glass. It is usually combines with other preprocess such as Edge Working, Drilling, Cutting, Screen Printing, Rolling Printing, Insulating, Laminating, Coating Solar Control or Low-E, Sand Blasted or Acid Etching etc…

|

|

EDGEWORKED

|

ACID OR SANDBLASTED |

ROLLED OR SCREEN PRINTED |

MORE INFORMATION

▪ Processing Sequence -- Tempered Glass cannot be drilled or edgeworked in any manner. Sandblasting or other surface treatments should be carried out prior to toughening as per AS1288 - 1994. Deep sandblasted patterns greater than 1mm are not permissible.

▪ Minimum Edgework Finish -- Minimum edgework finish requrement on Tempered Glass is a rough grinded edge.

▪ Distortion or Bowing -- Slight distortion or bowing may occur after toughening but is largely controllable. It will vary with substance, tint, surface treatment, size and shape of the glass.

▪ Heat-Soak Test -- To reduce the risk of Tempered Glass spontaneously breaking due to the presence of critical nickel sulphide (NIS) inclusions in the sheets of glass, it is advisable to put the Tempered Glass though an additional heat treatment known as the Heat-soak Test.

Tempered glass is a type of safety glass manufactured through controlled thermal or chemical treatment to significantly increase its strength and durability compared with ordinary annealed glass. During the tempering process, the glass is heated to a high temperature near its softening point and then rapidly cooled, creating compressive stress on the surface and tensile stress inside. This structure improves impact resistance, bending strength, and thermal stability. Tempered glass can withstand strong mechanical stress and sudden temperature changes. When broken, it shatters into small, blunt fragments instead of sharp shards, greatly reducing the risk of injury. Because of its high safety performance, clarity, and long service life, tempered glass is widely used in building windows, doors, curtain walls, shower enclosures, furniture, household appliances, and automotive applications.

Related Documents

NOVAL GLASS ENAMELLED TEMPERED GLASS EN12150 FRAGMENTATION TEST & BENDING TEST BY BV.pdf

3.5MB

LAMINATED

LAMINATED