VACUUM GLASS

Product description

INTRODUCTION

Noval Vacuum Glass uses special sealing materials and production technology to construct a high vacuum layer with a thickness of 0.1-0.2mm and a vacuum degree better than 10-2Pa between two layers of flat glass.

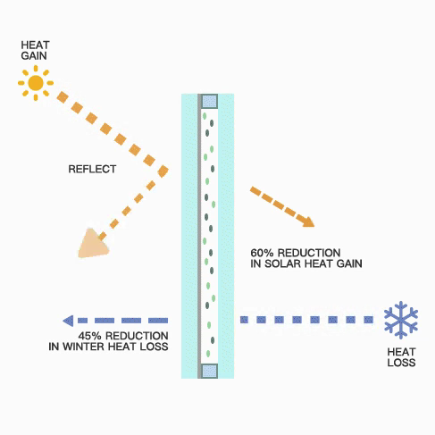

Due to the vacuum layer between the glasses, heat conduction and convection are basically non-existent, and sound cannot propagate. The LOW-E coating can reflect more than 95% of thermal radiation, so the heat insulation and noise reduction functions of vacuum glass far exceed the commonly used IGU.

FEATURES

Excellent heat insulation:

The thermal conductivity of vacuum glass is 3-5 times that of normal insulating glass, making it the most energy-efficient product in the current construction market. The U value can be as low as 0.3Wm2.K

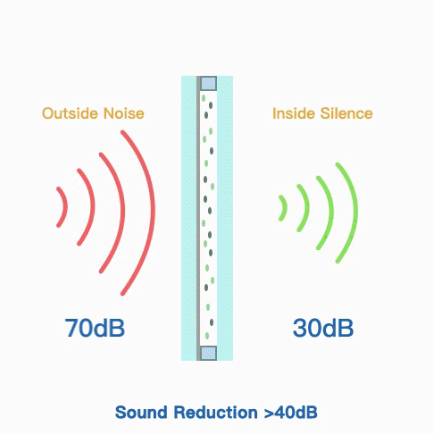

Outstanding sound insulation:

Vacuum glass has a weighted sound insulation of over 40dB, making it the glass product with the highest sound insulation performance.

Long service life:

Metal seal at the edge, low leakage rate, normal service life can reach more than 25 years.

High mechanical strength:

Fully tempered glass with a mechanical strength greater than 90Mpa.

Ultra-thin and light weight:

minimum thickness of 6.2mm, weight as low as 15KG/m2

Diversified combinations:

You can choose from a variety of LOW-E, clear glass, low iron, tinted glass, and reflective glass. It can also be used for composite photovoltaic power generation and fire-resistant glass.

APPLICATION

Architecture: new buildings can be directly used and are compatible with various door, window, and curtain wall profiles such as aluminum alloy, fiberglass polyurethane, and plastic steel. Old buildings can be directly replaced or installed on the original glass foundation.

Industrial household appliances: widely applied to the door glass of refrigerators, wine cabinets, ovens and other electrical appliances. It has the functions of transparency, visibility, and insulation. Vacuum glass has a lightweight structure and good insulation performance, which can perfectly solve problems such as condensation and energy waste.

Automotive: it is mainly used in the sunroof and side windshield of new energy vehicles to effectively reduce the transfer of external heat to the interior of the vehicle, without affecting the appearance of the vehicle, effectively improving the comfort of drivers and passengers, reducing the energy consumption of air conditioning, and increasing the driving range.

Key words:

Related Documents