WELDING GLASS

Product description

INTRODUCTION

Welding leases, also known as welding glass, protective lens, protective welding glass, welding goggle lens, is the main components of welding mask and laser goggle.

Welding is a process that uses heat and pressure to join metals together. One instance of welding hazards is the damage it can cause to your eyes because of the visible light. This can cause “flash blindness” like red, tearful eyes and even blind spots in your vision which is why it is important to wear the correct eye protection while welding

Welding glass helps to protect welders against the above mentioned situation. Welding glass can prevent infrared and ultraviolet through effectively as well as decrease the incident visible light, thereby protecting the worker's eyes. At the Meanwhile, workers can still observe the working condition clearly.

APPLICATION

Shade No.4 is used for backman like Steel Roller, fireman on blast furnance.

Shade No. 5 to 14 is used for gas and arc welding, brazing, or torch cutting

Shade No.5 to 6 fit for arc welding under 30A

Shade No.7 to 8 fit for arc welding from 30A to 75A

Shade No.9 to 11 fit for arc welding from 75A to 200A

Shade No.12 to 13 fit for arc welding from 200 A to 400A

Shade No.14 to 16 fit for arc welding over 400A

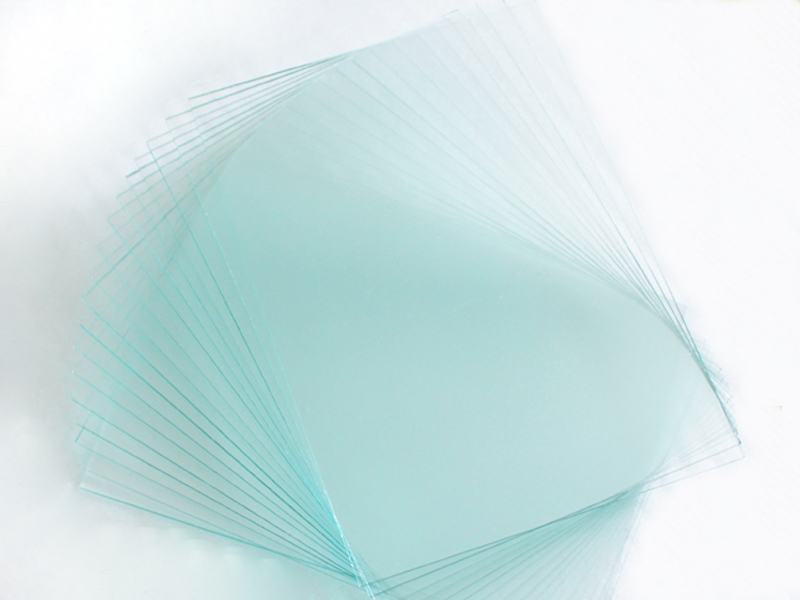

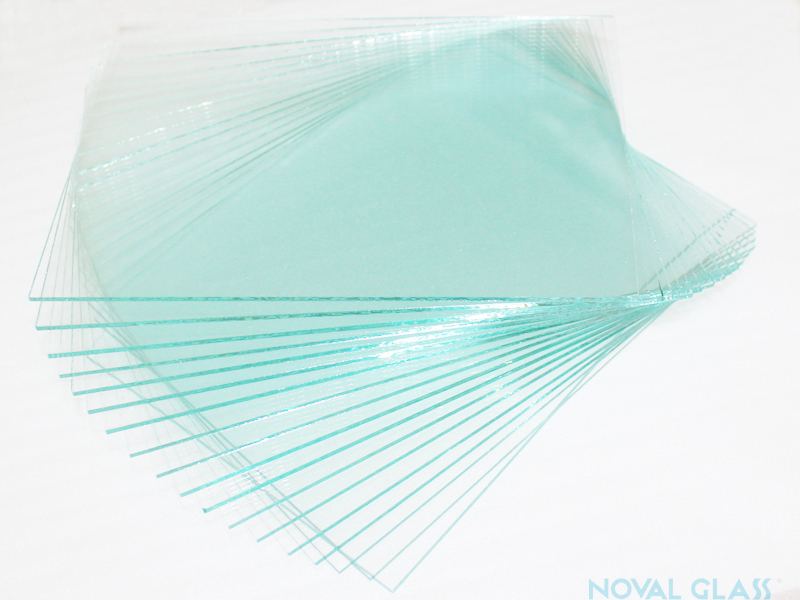

PRODUCTS PHOTO

CLEAR WELDING GLASS

| SHEET GLASS | FLOAT GLASS |

THICKNESS | 1.5MM, 1.8MM | 2mm, 3mm |

ADVANTAGE | Better Price | better formation of image |

COLOR | Transparent Clear | |

MATERIAL | Glass | |

SIZE | 108*51mm, 165*100mm, 170*120mm, 180*130mm | |

REMARK | Size can be customized. | |

BLACK WELDING GLASS

THICKNESS | 2mm, 3mm | ||

SHADE NO. | DIN 4-16 | ||

COLOR | Black, Golden, Silver | ||

MATERIAL | Glass | ||

SIZE | 2mm | 51*108mm, 30*110mm, 89*109mm, 90*110mm, 18*110mm | |

3mm | 75*98mm, 50*100mm, 50*105mm, 83*108mm, 50*110mm, 55*110mm, 60*110mm, 80*110mm, 80*110mm ,90*110mm, 110*165mm, φ50mm. | ||

REMARK | Size can be customized. | ||

SHADE NO. | UV TRANSMITTANCE | VISIBLE LIGHT TRANSMITTANCE | IRT | |||

313nm | 365nm | MAX | MIN | 700~1300μm | 1300~2000μm | |

DIN 4 | 0.0003 | 0.95 | 8.5 | 3.2 | 6.4 | 5.4 |

DIN 5 | 0.0003 | 0.3 | 3.2 | 1.2 | 3.2 | 3.2 |

DIN 6 | 0.0003 | 0.1 | 1.2 | 0.44 | 1.7 | 1.9 |

DIN 7 | 0.0003 | 0.037 | 0.44 | 0.16 | 0.81 | 1.2 |

DIN 8 | 0.0003 | 0.013 | 0.16 | 0.061 | 0.43 | 0.68 |

DIN 9 | 0.0003 | 0.045 | 0.061 | 0.023 | 0.2 | 0.39 |

DIN 10 | 0.0003 | 0.0016 | 0.023 | 0.0085 | 0.1 | 0.25 |

DIN 11 | 0.0003 | 0.0006 | 0.0085 | 0.0032 | 0.05 | 0.15 |

DIN 12 | 0.0002 | 0.0002 | 0.0032 | 0.0012 | 0.027 | 0.097 |

DIN 13 | 0.000076 | 0.000076 | 0.0012 | 0.00044 | 0.014 | 0.06 |

DIN 14 | 0.000027 | 0.000027 | 0.00044 | 0.00016 | 0.007 | 0.04 |

DIN 15 | 0.0000094 | 0.0000094 | 0.00016 | 0.000061 | 0.003 | 0.02 |

DIN 16 | 0.0000034 | 0.0000034 | 0.000061 | 0.000029 | 0.003 | 0.02 |

PRODUCTION

PACKING

Key words:

Related Documents