FUSED GLASS

Product description

INTRODUCTION

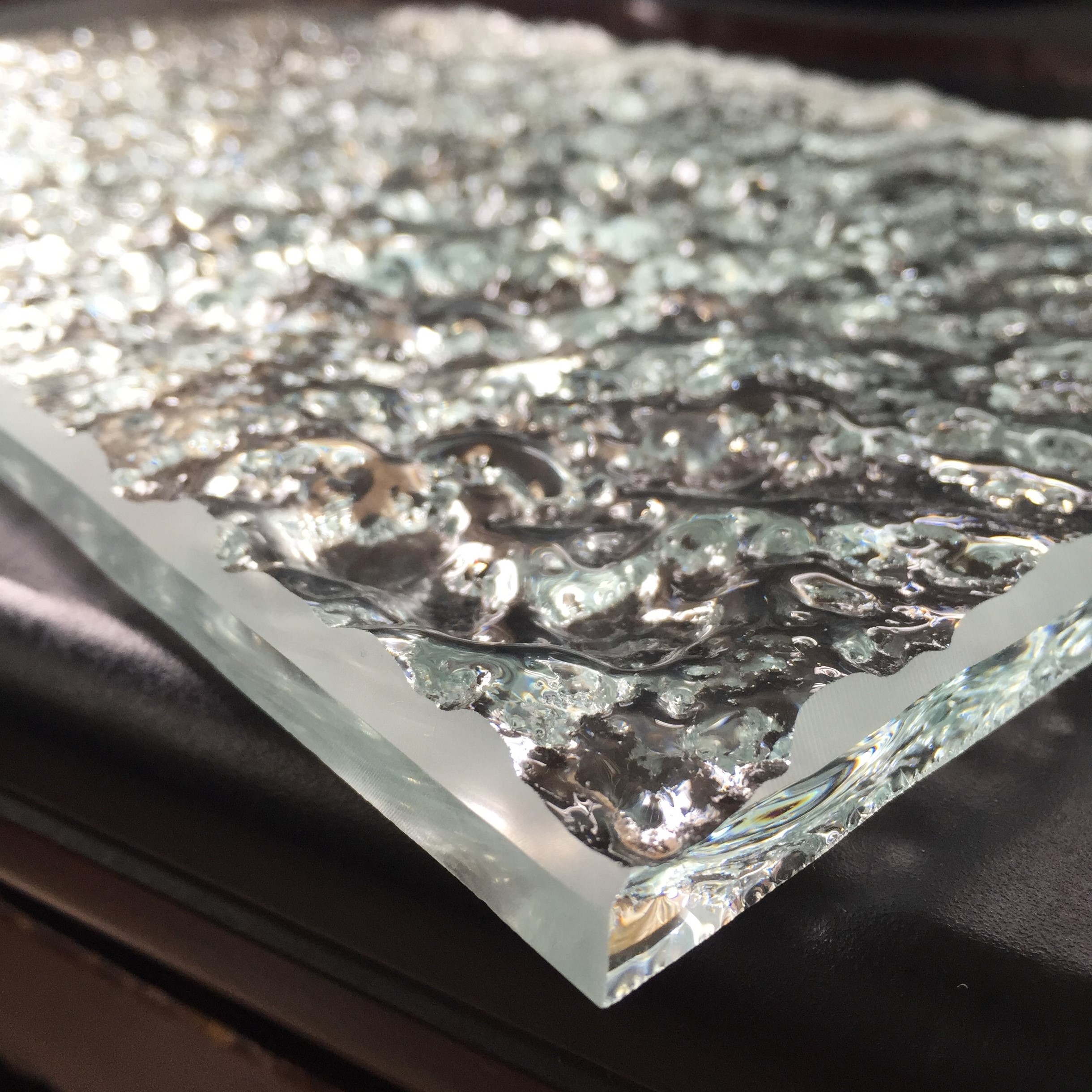

Fusing glass is the technique of layering thin sheets of glass on prefabricated mould and firing in a special oven (called a kiln) at temperatures of up to 800ºc for hours at a time. The piece and then allowed to cool over a set period of time to produce a fully fused and strong finished product. That is the basics anyway, it's actually a lot more complicated than that! Many different techniques can be applied to change the glass in different ways.

FEATURES

Art glass type -- Kiln casting art glass, fused glass, slumped glass

Thickness available -- 6, 8, 10, 12, 15 and 19mm. Or get thicker by laminating 2 layer glass.

Maximum size -- 2440*3660mm

Glazing options -- Tempering, laminating, drilling holes, hand polishing, bending, notching and shape cuts.

Glass material -- Clear float glass, tinted glass

Textures -- Over 30 unique textures, including sand, relief pattern, cloud, stone, waves, water flow etc.

Safty glass process -- Glass within 19mm thick can be tempered.

Colors -- Customized. Coloring methods including: tinted glass, painting, fused color.

Packing -- Standard exporting packing. Wooden crate with shock-proof material inside.

APPLICATION

Commercial & hospitality -- Glass curtain walls, fountains, doors, room dividers, tabletops, reception desks, glass mural walls and signage.

Restaurants -- Signage, booth dividers, doors, windows, decorative glass walls, tabletops, fountains, light sconces, vases and ornamental details.

Residential -- windows, tabletops, room dividers, privacy windows, works of art, bathroom and kitchen countertops, sinks, and shower enclosures

Furniture -- Contemporary designer furniture such as tables and fire screens by Meltdown artists. Fabrication of custom commissioned furniture.

Liturgical -- Church and chapel windows, room dividers, religious theme art screens, baptism bowls and religious art work.

MANY COLOR OPTION

Related Documents